The Jaapsa FC-60 System

The Jaapsa FC-60 System is a reinforcement based on carbon fibers and rods, with high quality and high resistance polymers to reinforce structures by forming an external laminate to the element.

This is a system for structural replacement. The use of latest innovation composite materials, such as the Jaapsa FC-60 System, reinforces and repairs existing reinforced concrete structures, structures with deterioration, corrosion, design or construction errors, use modifications or increased loads.

This innovation is used to reinforce, restore and repair. In addition, it gives an increase in seismic resistance capacity, being the most economical alternative.

These materials have been used to reinforce bridges and buildings around the world. Rigorous structural and durability tests were performed to gain acceptance from Ministries and Departments of Transportation worldwide. The Jaapsa FC-60 system is enhanced by high mechanical resistance rod compounds.

Works carried out with Jaapsa FC-60 Systems

- Crack and fissure injection

- Repair and reinforcement of columns, beams, concrete slabs

- Repair and reinforcement of Masonry

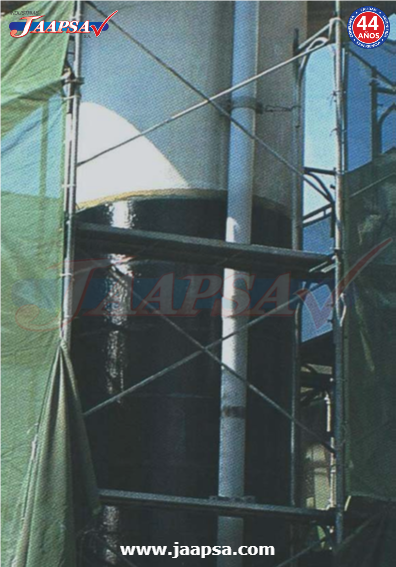

- Repair and reinforcement of chimneys, silos, ponds, ducts, pipes

- Repair and reinforcement of wooden structures

- Seismic rehabilitation

- Retrofit structures

- Underwater / coastal repair

- Advanced fire protection

They are also used to:

• Increased load.

• Seismic reinforcement.

• Repair of impact damage.

• Extension of the service life.

• Remediation of construction errors.

• Corrosion damage repair and protection.

• Shear reinforcement of diaphragms.

• Reinforcement of rectangular or shear columns

ductility.

ductilidad.

• Reinforcement of beams and slabs for bending or

cutting.

cortante.

• Reinforcement of walls of

masonry or concrete

• Reinforcement of column beam joints

• BT / JT and Superanclas connections.

• Changes of use.

• Corrosion

• Increased loads

• Rehabilitation of pipes.

• Jackets for marine structures.

• Explosion mitigation.

Process for Reinforcement

- Structure inspection

- Analyze the existing structure. Determine causes for reinforcement.

- Execute the Reinforcement Project.

To do this, analyze the structure considering the different techniques, to reinforce, depending on the types of efforts (tension, compression, bending, stability, constant, etc.) required in the elements.

• Rigidize the structure (Inclusion of shear walls, steel diagonals, etc.)

• Section hitch.

• Composite construction. (FRP) (STEEL) etc.

• Post tensioning inside and / or outside.

• Reduction of efforts and / or load.

• Inclusion of metallic structures to reduce lights.

• Etc.

A balance must be struck between cost, performance, aesthetics, space, urgency, difficulty, and safety.

Advantages of Carbon Fiber and Glass

Light weight 20% the weight of Steel

It is not Corrosive Resistant to chemical attacks

Easy to apply Installation in Limited Access Areas, Fiber cloth can be cut to desired dimensions

Versatile Fits geometries, Easy to Transport

Minimal thickness 1mm Installed

Material Properties

Modulus of Elasticity:

E = (700,a 2’300, ) Kg/cm2

Breaking Stress - Tension:

Fu = (15, a 40, )Kg/cm2

Failure Unit Deformation:

Mbrace cf 130 – cf 130 ou =0.016 mm/mm